There are various methods of nanofibers production. One of the most flexible and cost-effective is electrospinning, allowing formation under the influence of high electrical voltage of long, continuous fibres with diameters ranging from few nanometers to several micrometers. Electrospun nanofibers are created from electrically charged jets of polymer solution or polymer melt. Unusual properties of resulting fibers predispose them for plenty of applications with the most promising being nowadays tissue engineering.

Observation of electrospinning process started at the end of XIX century and continues during XX century (Rayleigh, Zeleny, Formhals, Baumgarten). Since the 1980s and especially in recent years, the electrospinning process has regained more attention due to a surging interest in nanotechnology. In fact, the name for this process "electrospinning'' derived from "electrostatic spinning'', is a relatively new term, which appeared around 1994.

How does it work?

Electrospinning process

Electrospinning process

Source: Ning Zhu, Xiongbiao Chen ,,Biofabrication of Tissue Scaffolds'',

in book entitled ,,Advances in Biomaterials Science and Biomadical Applications''

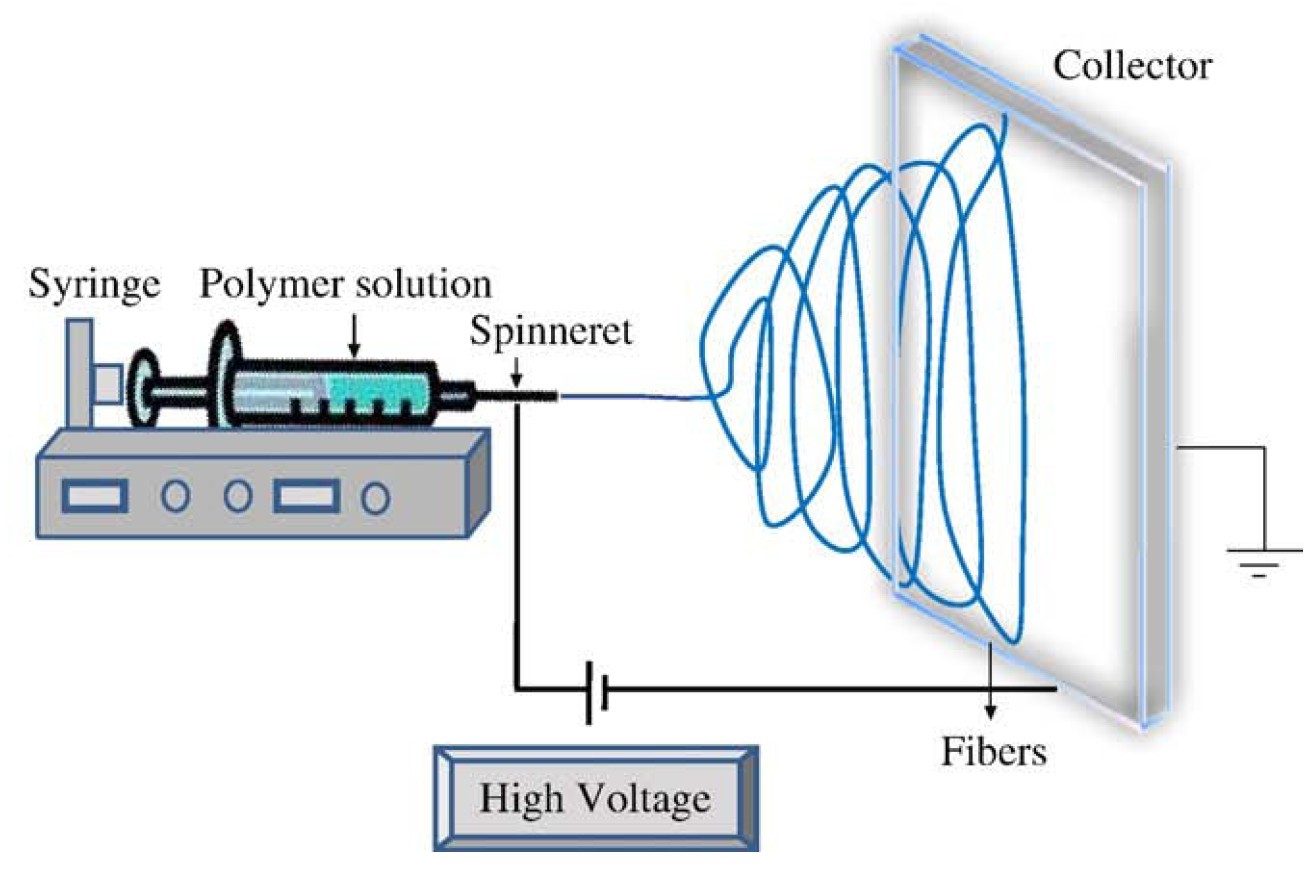

Electrospinning involves the use of a high voltage (commonly from 5 to 30 kV) applied classically between a needle of a syringe, filled with molecularly entangled polymer solution. The solution is pumped through a syringe at a constant rate, forming a droplet at the end of the needle. When the surface tension is overcome by electrostatic repulsion of charges within the solution, the jet is ejected, moving then toward the metallic collector which is usually grounded. The solvent evaporates during jet traveling, while the jet is elongated at very high strain rates, ranging from 100 to 1000 s-1. The structure of nanofibers collected finally is far from thermodynamic equilibrium (metastable structures).

The most important forces acting first on a drop and then on a traveling jet are:

- an external electrostatic field that acts directly on charges within polymer jet but also results in additional electric polarization of flowing material

- electrostatic repulsion among the charges

- surface tension, trying to reduce repulsion between charges

- the forces related to the viscoelasticity of polymer.

The formation of nanofibres is mainly caused by repulsion occurring among charges resulting in high stretching of the polymer stream. Stream initially flows in straight. On the way to the collector, various instabilities occur. The jet is elongated by bending and whipping processes caused by electrostatic repulsion initiated at small bends in the fiber until it is finally deposited on the collector. The elongation and thinning of the fiber resulting from these bending/whipping instabilities lead to the formation of uniform fibers. The spiral movement of the stream substantially increases the path between the needle and the collector, resulting in a significant stretching (nanometer diameter).

Currently, there are two standard electrospinning setups, vertical and horizontal. The process can also be carried out using two several independent syringes/needles with different solutions.

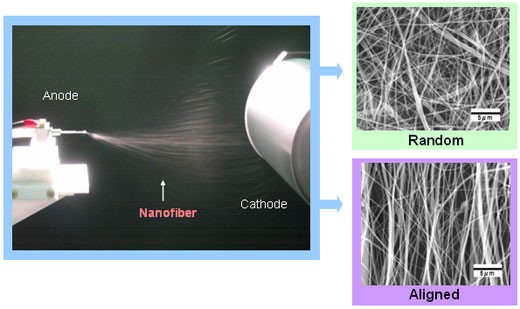

Using a rotating collector we can affect the arrangement of fibers

Source: www.cosmobio.co.jp/export_e/products/detail/products_hks_20090105.asp?entry_id=1643

Parameters affecting the process of electrospinning

Properties of polymer solution, which most significantly affect the process of electrospinning:

- solution viscosity depending mostly on polymer molecular weight as well as polymer concentration,

- solution surface tension,

- solution electric conductivity,

- dielectric constant of the solvent.

Initialization of electrospinning process needs overcoming of surface tension of solution by electric interactions between charges. The surface tension of commonly used solvents is in the range of 20 - 40 mN/m2, with an exception of the very high surface tension of water. One of the conditions for electrospinning is that the viscosity should be above some critical value to prevent the breakage of the jet. The higher molecular weight of polymer (viscosity of solution) results in more entanglements, preventing the breakage of the fibers and formation of beads.

The second group of parameters that affect the electrospinning process are processing conditions:

- applied voltage,

- flow rate of solution,

- a type of a collector,

- diameter of a needle,

- the distance between a needle and a collector.

The third group are environmental parameters:

- temperature

- humidity,

- pressure.

Materials

Among polymer nanofibers are both synthetic like PCL, PLLA, PLA, PGA, PLGA, PU etc. as well as natural like collagen, gelatin, chitosan, fibrin.

Advantages

- simple and low-cost equipment,

- mimicking of the architecture of native tissue,

- the possibility of scaling the process,

- possibility to control fiber morphology,

- a wide range of polymers can be processed by electrospinning.

Disadvantages

- solvents can be toxic,

- problem with obtaining 3D structures as well as sufficient size of pores needed for biomedical applications,

- process depends on many variables.

Applications

Nanofibres produced by electrospinning can be used for tissue engineering, analytical chemistry, filtration techniques, electronic or environmental engineering. In tissue enginnering, electrospinning of nanofibers is used for the fabrication of scaffolds mimicking natural ECM. This method is mainly used for the production of artificial skin, implant fo the vascular surgery, drug delivery systems bone, and wound dressings.

Nanofiber mats used for medical dressings

Nanofiber mats used for medical dressings

Source: M. Mahfuzur Rahman Chowdhury, ,,Electrospinning Process. Nanofiber and their application'',

http://www.cottonbangladesh.com/January2009/ElectroSpinning.htm

Literature:

- Bhardwaj N., Kundu S.C. ,, Electrospinning: A Fascinating Fiber Fabrication Technique'', Biotechnology Advances 28 (2010), 325-347

- Baranowska- Korczyc A., ,,Półprzewodnikowe sensory oparte na nanowłóknach otrzymanych metodą elektroprzędzenia'', PhD thesis, Instytut Fizyki PAN, 2012

- Ramakrishna S., Fujihara K., Teo W.E., Lim T.C., Ma Z. "An Introduction to Electrospinning and Nanofibres'', World Scientific

- Vasita R., Kattai S.D. ,,Nanofibres and their applications in tissue engineering'', International Journal of Nanomedicine 2006: I (I) 15-30